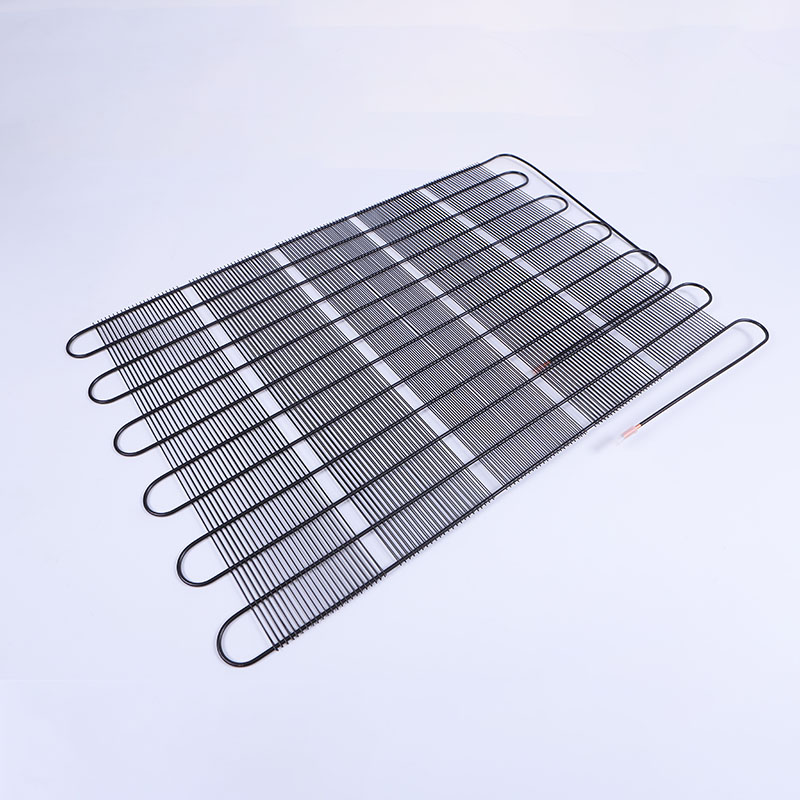

Hlau tube condenser rau lub freezer

Peb muaj kev tswj xyuas nruj heev ntawm vuam zoo vuam zoo:

1. Lub zog vuam ntawm cov hlau hlau yuav tsum tsis pub tsawg tshaj 100N.

2. Tag nrho cov xov hlau detachment thiab cuav solder pob qij txha yuav tsum tsis txhob ntau tshaj 5 ‰ ntawm tag nrho cov tooj ntawm solder pob qij txha; Cov ntsiab lus vuam ntawm ob qho kawg ntawm cov hlau xaim thiab tag nrho cov ntsiab lus vuam ntawm cov npoo sab nraud ntawm lub condenser steel hlau tsis raug tso cai kom tawm welded los yog tsis zoo welded; Tib cov hlau hlau tsis raug tso cai kom muaj ob lossis ntau qhov sib txuas sib txuas los yog vuam tsis raug.

Qhov saum npoo yog kho nrog cathodic electrophoretic txheej, uas muaj kev ua haujlwm ntawm corrosion kuj zoo heev, kom ntseeg tau tias lub condenser tuaj yeem ua haujlwm ruaj khov rau lub sijhawm ntev txawm tias nyob hauv qhov chaw ntub thiab corrosive. Tsis tas li ntawd, peb nruj me ntsis tswj kev huv hauv tsev kom ua tau raws li qhov yuav tsum tau muaj ntawm R134a thiab CFC cua txias tshuab, kom ntseeg tau tias muaj txiaj ntsig zoo thiab muaj txiaj ntsig zoo rau ib puag ncig.

| R134a-cooling-system tube qauv | |

| Residual noo noo | ≤ 5mg / 100cm³ |

| Residual impurity | ≤ 10mg / 100cm³ |

| Residual ntxhia roj | ≤ 100mg / 100cm³ |

| Cov tshuaj chlorine residual | ≤ 5vloppm |

| Residual paraffin | ≤ 3mg / cm³ |

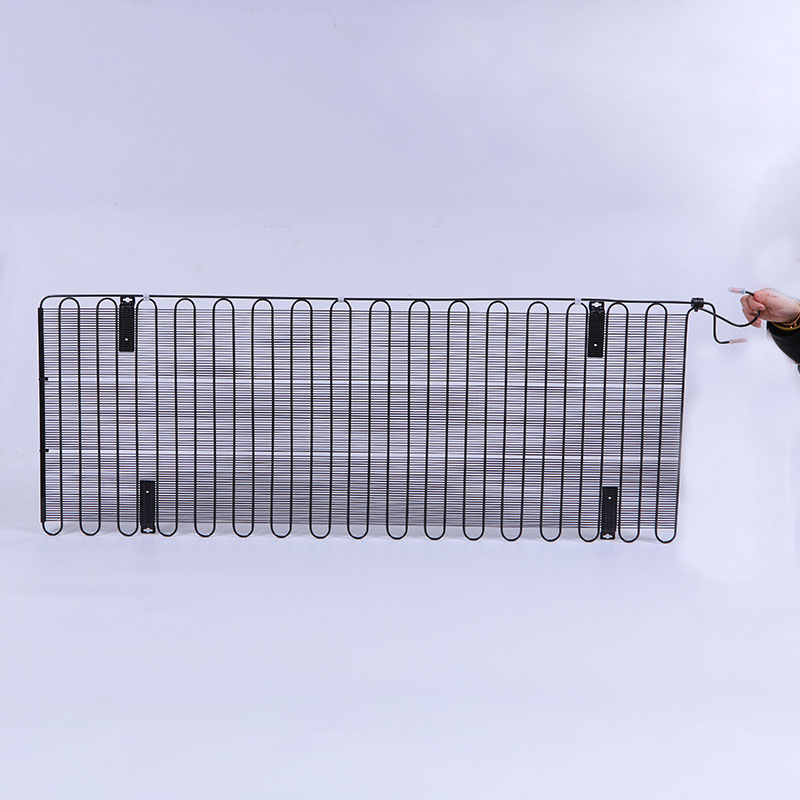

Hlau raj condensers rau lub freezers yog dav siv nyob rau hauv ntau yam scenarios, xws li tsev loj, khw muag khoom, thiab tsev noj mov, kom tswj tau cov freshness thiab saj ntawm zaub mov thiab dej haus, thiaj li los txhim kho cov neeg siv khoom txaus siab. Nyob rau tib lub sijhawm, nws kuj tseem tsim nyog rau cov tub yees hauv tsev, muab cov cua txias kom zoo, txuag hluav taws xob thiab kev daws teeb meem ib puag ncig, ua rau tsev neeg lub neej zoo dua.

Xaiv peb cov xaim raj condenser rau koj lub tub yees kom ua tiav qhov kev ua haujlwm txias txias thiab muab kev paub zoo rau cov neeg siv khoom!

RoHS ntawm bundy tube

RoHS ntawm cov pa roj carbon tsawg